4286 days accidents |

|

*Compliance with commitment |

|

The MAG-WELL equipment from MAG-TEK helps you to increase the production and reduce the costs of the well with problems of scales, paraffin and asphaltenes

Reduces significantly the need of use conventional treatments as hot oil, mechanical or chemicals

Helps to increase the production due the absence of clogging by paraffin and asphaltenes in the pumps, separators and associated equipment’s

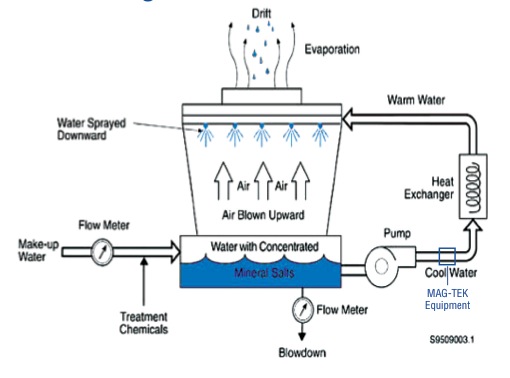

Helps to remove scales and inhibit the formation of new deposits en pumps, pipes, heat exchangers, separator and associated equipment´s

Keeps the pipes off corrosion and tubercles due the scales deposits

Reduces the accumulation of sediments in bulk tanks

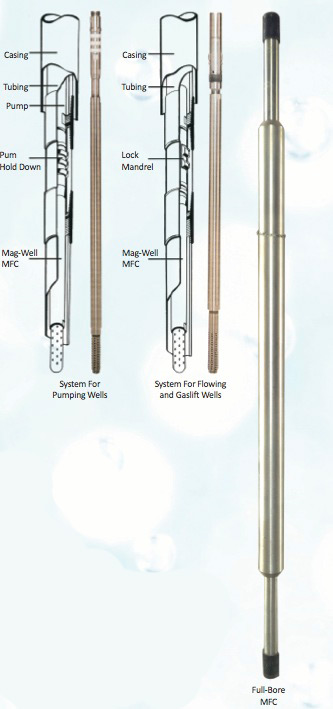

High tech magnetic control fluid tool developed by MAG-WELL Inc., protected by the American patent number 5,178,757

A specific design to treat well fluids. Flowing through a magnetic vortex of the tool treats the fluid.

Controls the accumulation scales of paraffin and asphaltenes in production tubing and packers

Increases the production by reducing the scale and wax accumulation

Uses high intense magnets to generate a magnetic field which induces the fluid treatment

The tool is design specifically for the use on field

Patrimonial property software is used to analyze variables of well production and evaluate the tool design.

Through the process known as "polymerization", the agglomeration of paraffin and asphaltenes results in the creation of solids, the diesel begins to degrade immediately after refining.

Diesel fuel is inherently unstable, therefore decomposition and degradation of fuel is an inevitable natural process. This process can be accelerated through storage, exposure to heat, irregular engine pressures, microbial condensation contamination, cracking and mixing problems, etc.

When the sediment levels suspended in the diesel are oversaturated it results in damages to injectors and associated equipment. Over time, the accumulation of waste produces mud; which needs immediate attention, failure to respond to symptoms can lead to overheated filters, power loss, excessive hydrocarbon emissions, injector and motor failures.

A magnetic field will interact with any substance that carries a charge in any fluid. The electrical charges on the glass cores and the growth crystals are affected at the surface. This alters the growth of crystals in general and in specific planes. As crystals grow differently in size, shape, rate and number, their solubility or the level of supersaturation in the liquid are altered, inducing inlays to dissolve.